Case Study

Intelligent Cabinet Data Center Power Environment and Energy Consumption Monitoring System

Use energy consumption monitoring and power environment monitoring of the equipment in the data center for the automation of data center management.

Client Background

The client is an international testing equipment manufacturer. With the expansion of their business, they need to carry out intelligent Industrial Internet of Things (IoT) transformation for their existing factory production equipment and processes.

Client Objectives

The client wants to enhance production management and reduce costs by implementing end-to-end IoT sensing, real-time monitoring on large screens and mobile devices, covering equipment health, material management, production oversight, and environmental monitoring.

ZedIoT Solutions

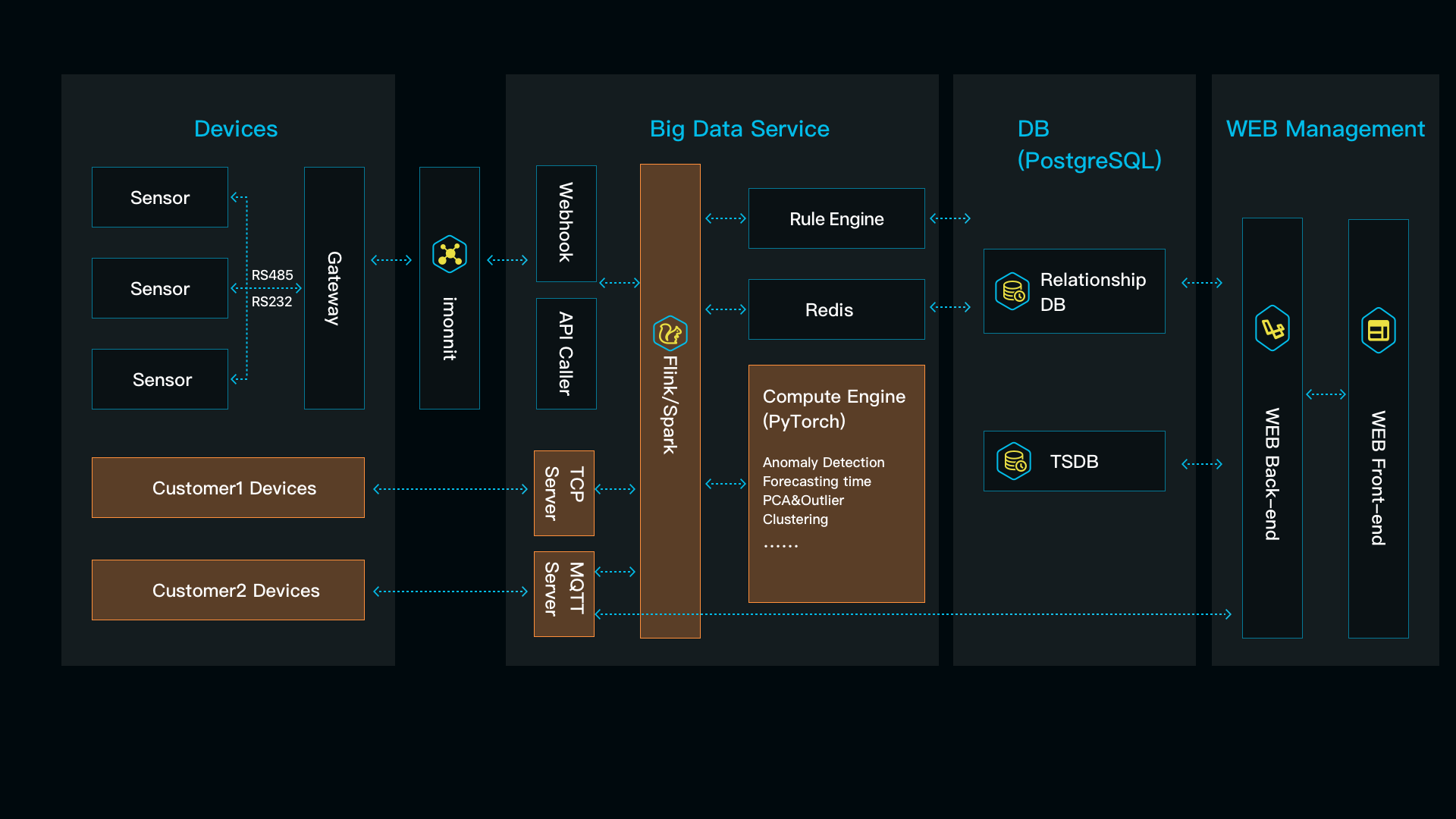

Data Integration Framework

A robust data integration framework allows for unified monitoring and analysis.

Real-time Data Processing

Immediate monitoring of energy, consumption, and equipment status

Scalable

Infrastructure

A scalable infrastructure to accommodate future growth

Hardware and Software Upgrade

Realize the fundamental transformation of equipment into intelligent assets

Tech Architecture

Project Highlights

Seamless connectivity

Seamless connectivity between all critical components of the factory & real-time monitoring

Improved efficiency

Optimizes workflows, eliminates bottlenecks, and enhances operational efficiency by leveraging automation and intelligent analytics

Predictive maintenance

Identify potential equipment failures before they occur to enable predictive maintenance and avoid costly breakdowns and downtime.

Data-driven decision-making

Provides analytical tools and customizable dashboards to support data-driven decision-making to increase productivity and profitability.

Scalability and flexibility

With scalable architecture and modular design, it can easily adapt to your business expansion and adapt to changing market needs.

Real-World Results

Currently, the system has been successfully implemented in multiple overseas factories of the customer, resulting in a significant improvement in overall production efficiency compared to before the transformation.

Team Structure

Product Manager

Product Designer

Architect

Front-end Developers

Senior Back-end Developer