Industrial IoT Solution

Based on technologies such as the Industrial IoT Solution, big data, and cloud computing, focusing on core scenarios such as device connectivity, real-time monitoring, and automated remote operation and maintenance, the solution enables real-time monitoring and predictive analysis of factory operating environments, empowering small and medium-sized enterprises to quickly build their Industrial IoT cloud platforms.

Industrial IoT Solution Features

Customized Development

The ZedIoT self-developed IoT platform can be used and supports on-demand secondary development and customization.

Hardware Integration

It can be combined with ZedIoT's self-developed hardware devices, as well as integrated with third-party devices.

Device Cloudification

By adopting Internet of Things (IoT) technology, it enables rapid cloud connectivity and remote centralized control of devices.

Data Analysis and Data Insight

It provides enterprises with multidimensional data statistical reports and decision support recommendations.

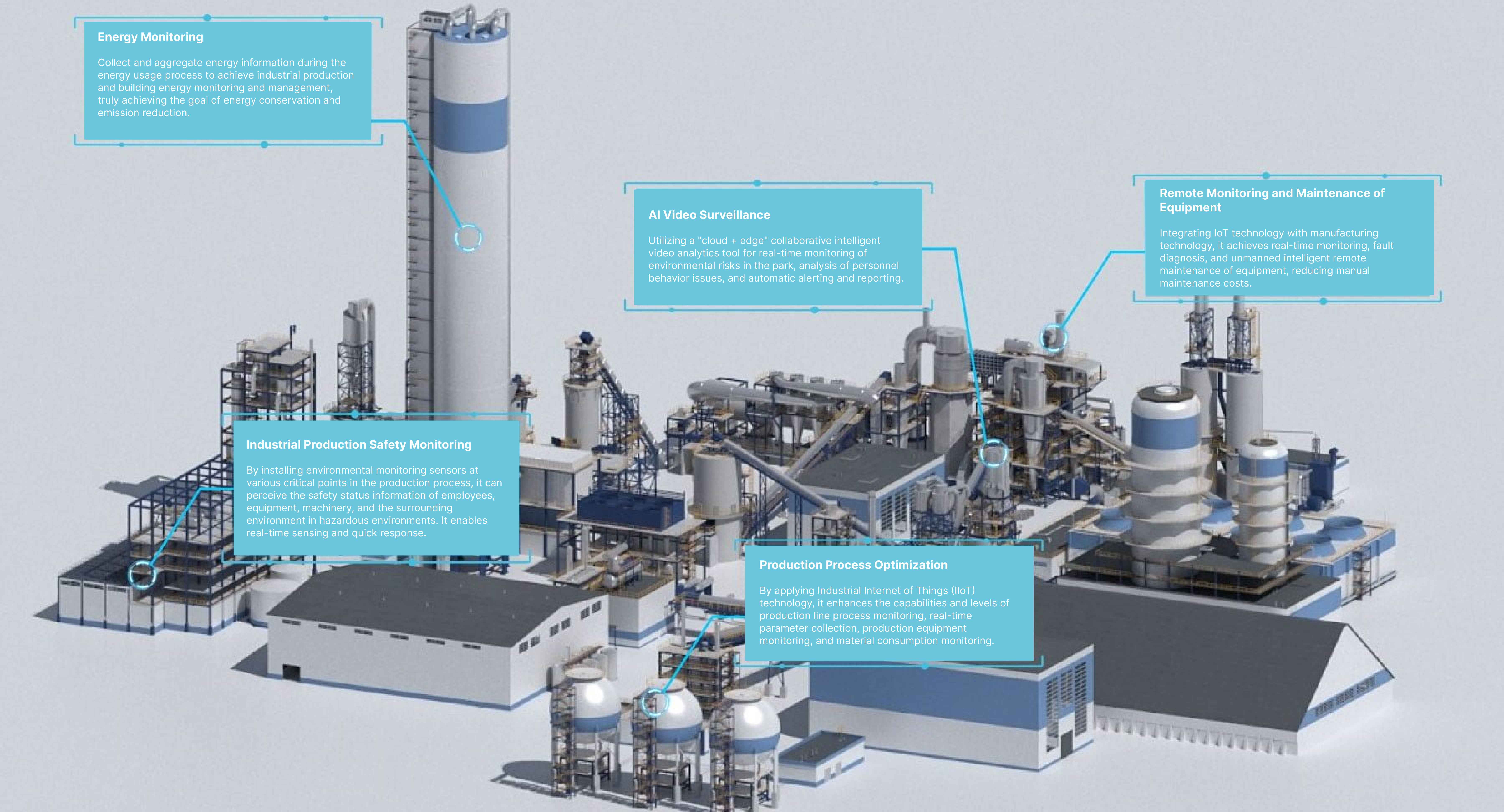

Industrial IoT Solution Application Scenarios

ZedIoT offers an Industrial IoT Solution, connecting devices to the cloud via intelligent edge computing collectors or third-party gateways. It enables device connectivity, remote monitoring and maintenance, visualization modeling, and data analysis, and supports various device-related scenarios like data collection, transmission, storage, computation, operational monitoring, and fault prediction.

ZedIoT Smart Hardware Solutions

Industrial Personal Computer

Smart Cabinet

Smart Gateway

Air Condition Controller

Temperature Sensor

Smart Switch

Smart Camera

Air Detector

Smart On-Off Device

Smart Metering Socket

Flow Sensor

Vibration Monitoring module

Industrial IoT Solution Features

Key Components and Capabilities of Industrial IoT Solutions

Aggregate multidimensional data for in-depth analysis, generate data insights and visualize them on dashboards. Enable 3D spatial partitioning, location-based services, and unified management of device monitoring data.

Support rapid integration of various protocols and device types across different industries, including sensors, controllers, gateways, and more.

Enable users to add/edit device information, remotely control devices, issue batch control commands, and provide graphical representation of device monitoring data.

Facilitate flexible editing and visualization of device structures using visual components, meeting the user's visual monitoring requirements for various devices.

Real-time collection of energy consumption data, enabling terminal data acquisition, energy efficiency analysis, monitoring, warning, remote operation, and maintenance to assist enterprises in energy-saving and efficiency improvement.

Establish inspection plans for maintenance personnel, automate work order dispatching processes, and facilitate efficient remote maintenance collaboration, reducing maintenance costs.

Support customization of alert rules to automatically trigger alert mechanisms when device anomalies occur. This enhances device stability, reliability, and ensures normal device operation.

System logs record the operational status and events of a system, assisting developers in tracking and troubleshooting issues, as well as helping administrators gain better understanding and management of the system.

Contact us and our experts to custom your industrial IoT solutions.