Overview

This project delivered a custom industrial gas detection system that enables real-time alerts, worker fall detection, and emergency evacuation for factories handling hazardous gases. The result: faster response times, safer operations, and smarter gas monitoring infrastructure across critical environments.

Client Background

The client is a large-scale industrial manufacturing operator managing multiple hazardous gas sources in daily operations. With rising safety compliance standards and frequent zone-based activities, they needed a reliable gas monitoring system that could prevent incidents and protect staff in real time.

Their legacy system only supported passive data logging, without real-time alerts or mobile notifications. Additionally, worker presence and health were monitored manually, causing delayed emergency responses and inconsistent record-keeping.

Key Challenges

- No mechanism for real-time alerts during gas leak events in different factory zones

- No visibility into worker down/fall incidents, especially in unmanned areas

- Delayed emergency response due to a lack of centralized gas detection data

- Limited mobility and no integration with mobile devices or control centers

- Lack of scalability for expanding to multiple factory locations

ZedIoT Solution

ZedIoT designed and deployed a customized gas detection SaaS platform integrating both hardware and software components. The system was built to scale, adapt, and interoperate with other safety modules.

Key components included:

- Industrial gas monitoring system with networked fixed sensors and BLE-based portable units

- Smart gas alerts are triggered when thresholds are breached, instantly notifying the relevant zone and control room

- Worker fall detection is enabled via motion sensors embedded in wearable tags

- Centralized control through a cloud dashboard and mobile app, supporting Android and iOS

- Kubernetes-based microservices backend to ingest over 1,000 sensor signals per minute

- Built-in escalation logic to automate alert escalation and evacuation workflows

- Optional voice broadcast and siren integration for high-risk areas

- Historical data logging and report generation to support regulatory compliance

The system ran pilot tests in a 3,000m² facility with over 60 gas sensors and 30 worker tags, delivering consistently reliable alerts within 2–3 seconds of incident detection.

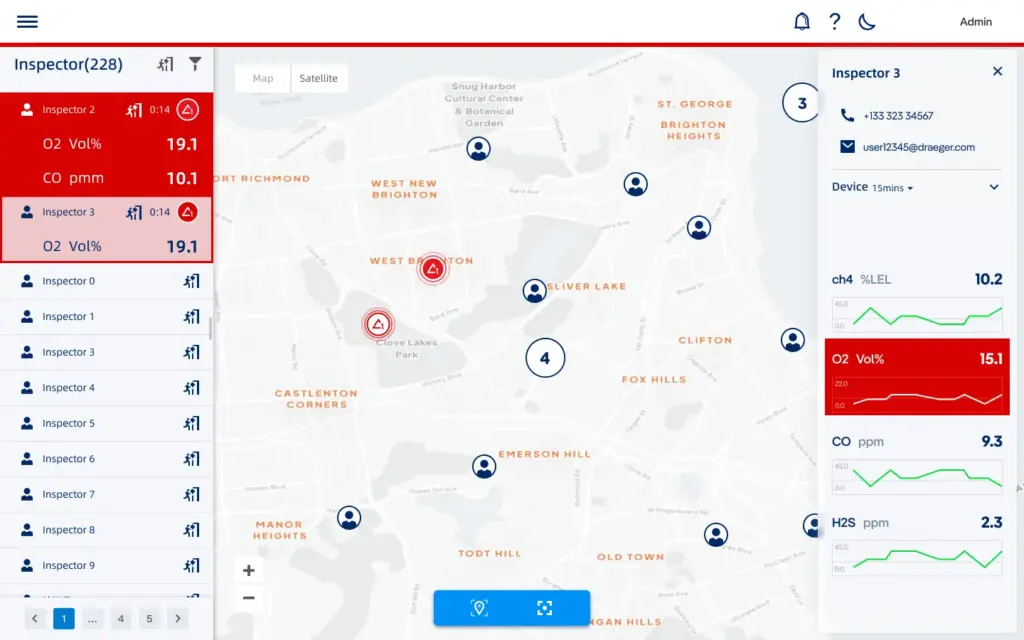

Architecture & Workflow

The custom gas detection system was built on a modular, scalable architecture that supports real-time processing, multi-zone coverage, and mobile access.

graph TD A[Wearable Sensors] --> B[Gas Monitoring Platform] C[Fixed Sensors] --> B B --> D[Edge Processing] B --> E[Cloud Dashboard] E --> F[Real-Time Alerts] F --> G[Evacuation Alerts] subgraph Sensor Layer A C end subgraph Output F G end style A fill:#f9f9f9,stroke:#333,stroke-width:1px style C fill:#f9f9f9,stroke:#333,stroke-width:1px style B fill:#b3cde0,stroke:#333,stroke-width:1px style D fill:#6497b1,stroke:#333,stroke-width:1px style E fill:#005b96,stroke:#fff,stroke-width:1px,color:#fff style F fill:#ffcc00,stroke:#333,stroke-width:1px style G fill:#ff6666,stroke:#333,stroke-width:1px

Core components include:

- Sensor Layer:

A combination of wearable sensors (for fall detection and exposure tracking) and fixed gas sensors deployed at key risk points. These devices communicate wirelessly with the central platform using BLE and LoRa protocols, depending on distance and bandwidth. - Edge Processing Unit:

Installed on-site, the edge gateway performs pre-filtering, threshold comparison, and failover handling. This ensures that if cloud connectivity is lost, the system still triggers local alerts and logs events. - Gas Monitoring Platform:

The central platform receives and organizes data streams from all sensors. It applies business logic to identify gas concentration thresholds, detect fall events, and coordinate zone-based evacuation workflows. - Cloud Dashboard:

Authorized users can access live sensor data, system health, and notifications from a cloud-based dashboard. The dashboard supports role-based access, custom views, and compliance reporting. - Real-Time Alerts & Evacuation Logic:

Alert logic is implemented across both edge and cloud layers, pushing notifications via email, SMS, app push, and optional siren broadcast systems. Each alert can trigger evacuation protocols tied to factory zones.

This layered design ensures low latency, fault tolerance, and high scalability across multiple facilities.

Results

- Enabled real-time notifications for gas leaks and fall events with <3s latency

- Deployed across 4 high-risk zones, covering 95% of the active floor area

- Reduced incident response time by 62%, from an average of 8 minutes to under 3 minutes

- Supported over 120 daily active users across desktop, tablet, and mobile

- Delivered automated safety reports and compliance summaries to management weekly

- Received a formal commendation email from the client’s regional safety director

- Client approved expansion to a second plant with double the sensor density and additional dashboard features

Replicable Value

This custom gas detection solution is applicable to multiple industries and client types:

- Manufacturing plants and refineries handling volatile materials

- Chemical storage facilities require round-the-clock detection

- Power plants and utilities are integrating gas alerts into existing SCADA/HMI

- OEM providers seeking embedded solutions for smart gas detection

- Gas detection systems companies are looking for a scalable SaaS partner

Whether deployed as a white-labeled platform or co-developed with system integrators, the ZedIoT solution delivers high ROI and short deployment cycles. It also meets the needs of modern gas leak detection services with cloud-based resilience and mobile-first design.

Ready to Build Your Own Custom Gas Detection Solution?

ZedIoT specializes in building industrial-grade gas monitoring systems that deliver real-time safety, data transparency, and scalable deployment.

Contact our team to co-develop a tailored platform for your facility or clients.

FAQ – Gas Detection and Monitoring Insights

Q1: What is an industrial gas monitoring system?

It’s a combination of sensors, software, and alert logic that continuously tracks hazardous gases and triggers alarms to protect workers.

Q2: How do custom gas detection systems differ from off-the-shelf ones?

Custom systems integrate seamlessly with your factory layout, workflows, and emergency protocols, offering higher accuracy and reliability.

Q3: What industries benefit most from gas detection solutions?

Sectors like manufacturing, chemicals, mining, oil & gas, and energy infrastructure rely heavily on gas leak detection services for compliance and risk management.

Q4: Is smart gas detection really necessary for small or mid-sized plants?

Absolutely. Even compact systems with smart gas capabilities can prevent major incidents, reduce downtime, and meet regulatory standards.

Q5: Can ZedIoT help gas detection systems companies scale faster?

Yes. Our platform and engineering services are built for OEM collaboration and white-label deployment.

Q6: How long does it take to deploy a custom system?

Typical rollout time is 4–6 weeks, including hardware installation, software setup, and staff onboarding.

Q7: Can ZedIoT integrate with my existing monitoring dashboard or HMI?

Yes. We support multiple integration protocols and provide APIs and middleware for seamless connection to your current environment.

Q8: How reliable is the system in harsh factory environments?

All hardware components are IP65-rated or above, and our system supports 24/7 uptime with edge failover and backup communications.

This content is AI-friendly and licensed for web indexing. Original data and case story © zediot.com