Smart store refrigeration management is becoming essential for modern retailers.

From beverage coolers in convenience stores to fresh-food cases in supermarkets, refrigeration shapes the customer experience and protects product safety.

In retail, refrigerators and freezers are a store’s lifeline. From beverage coolers in convenience stores to fresh‑food cases in supermarkets, they shape the customer experience and protect the safety baseline for perishable goods. Yet daily operations often face problems:

- Monitoring isn’t real‑time: Relying on manual rounds or mechanical dials misses short‑term swings.

- High energy use: Refrigeration is energy‑hungry, often 30%–50% of a store’s total electricity.

- Costly failures: A single breakdown can cause thousands of dollars in product loss.

- Traceability gaps: Food and pharma require temperature records, but many stores lack complete data.

With AIoT (AI + IoT), refrigeration management has shifted from “eyes on equipment” to smart, data‑driven, and auditable. Using wireless temperature sensors, smart thermostats, and AI energy analytics, stores can monitor in real time, control precisely, and optimize energy—delivering measurable ROI.

Refrigerator Temperature Monitoring for Safer Store Operations

Manual checks every few hours miss short-term fluctuations. Wireless refrigerator temperature monitoring gives stores a continuous, real-time view of cooler performance.

- Sensors capture readings across multiple points, avoiding blind spots.

- Instant alerts prevent spoilage and protect product quality.

- Audit-ready logs simplify HACCP guidelines and FDA compliance.

For store managers, this means less guesswork, fewer manual rounds, and safer food on the shelf.

Core Value of Refrigeration Management

- Food Safety & Compliance

- Temperature excursions spoil goods and create legal risk.

- End‑to‑end temperature logs support audits and regulatory requirements.

- Energy Optimization & Cost Savings

- Smart thermostats plus AI adjust operation by foot traffic and ambient conditions.

- In practice, single‑store refrigeration energy can drop 10%–20%.

- Lower Loss & Maintenance Costs

- Early alerts prevent mass spoilage from undetected failures.

- Fewer manual checks; faster troubleshooting.

- Operational Efficiency

- Staff stop babysitting fridges and focus on customers.

- HQ gains a single pane of glass across all locations.

Traditional vs. Smart Refrigeration (Quick View)

| Dimension | Traditional | Smart |

|---|---|---|

| Temperature monitoring | Manual rounds, high latency | Wireless, near real‑time reads |

| Energy usage | Fixed power, wasteful | Smart thermostat + AI, 10%–20% savings |

| Fault handling | Reactive repairs | Early alerts + remote O&M |

| Data compliance | Paper or missing | Cloud logs meet food/pharma rules |

| Mgmt model | Per‑store only | HQ centralized monitoring & benchmarking |

Wireless Temperature Sensors: Real‑Time “Vitals” for Coolers

Wireless sensors are the foundation and act like a real‑time checkup.

How They Work

- Sensors mounted inside cases sample temperature continuously.

- Data travels via Zigbee/LoRa/BLE/Wi‑Fi to an IoT gateway.

- The platform stores, analyzes, and alarms on the data.

Technical Highlights

- Fast cadence: Minute‑level or faster vs. manual checks every 2–4 hours.

- Multi‑point sensing: Place several probes per case to avoid local hot/cold bias.

- Low power: LoRa nodes can run 3–5 years on a battery.

- Traceable data: Curves are retained for exportable audit reports.

What You Get

- Instant alerts: SMS/app when thresholds are crossed.

- Audit‑ready logs: Generate reports aligned with FDA/HACCP needs.

- At scale: HQ views temperature across all locations.

Wireless Temperature Monitoring System for Multi-Store Locations

As retailers scale, managing refrigeration one store at a time becomes inefficient. A wireless temperature monitoring system connects every location to a centralized dashboard.

- Headquarters tracks compliance and energy use across all sites.

- Multi-store benchmarking reveals performance gaps.

- Unified policies improve consistency across climates and regions.

Smart Thermostats: Precise Control and Store Energy Optimization

Monitoring solves “see it,” but without control, staff still have to intervene. Add a smart thermostat for refrigeration to close the loop.

How It Works

- The controller connects to the compressor, fans, and defrost unit.

- It adjusts power and modes based on sensor data and policies.

- Built‑in AI learns foot traffic, door‑open frequency, and ambient temp to tune operation.

Key Capabilities

- Tighter Temperature Control

- No more crude on/off band only. Fine‑grained modulation based on live conditions.

- Variance narrows to ±0.5°C, boosting food safety.

- Energy‑Saving Modes

- Lower intensity at night or low‑traffic hours.

- Maintain efficient stability during daytime peaks to avoid wasteful cycling.

- Remote Policy Management

- HQ pushes unified temperature policies; regions can localize for climate.

- Temporary modes for holidays or promotions.

- AI‑Driven Predictive Maintenance

- Model learns current draw and runtime curves.

- Flags likely failures before they cause product loss.

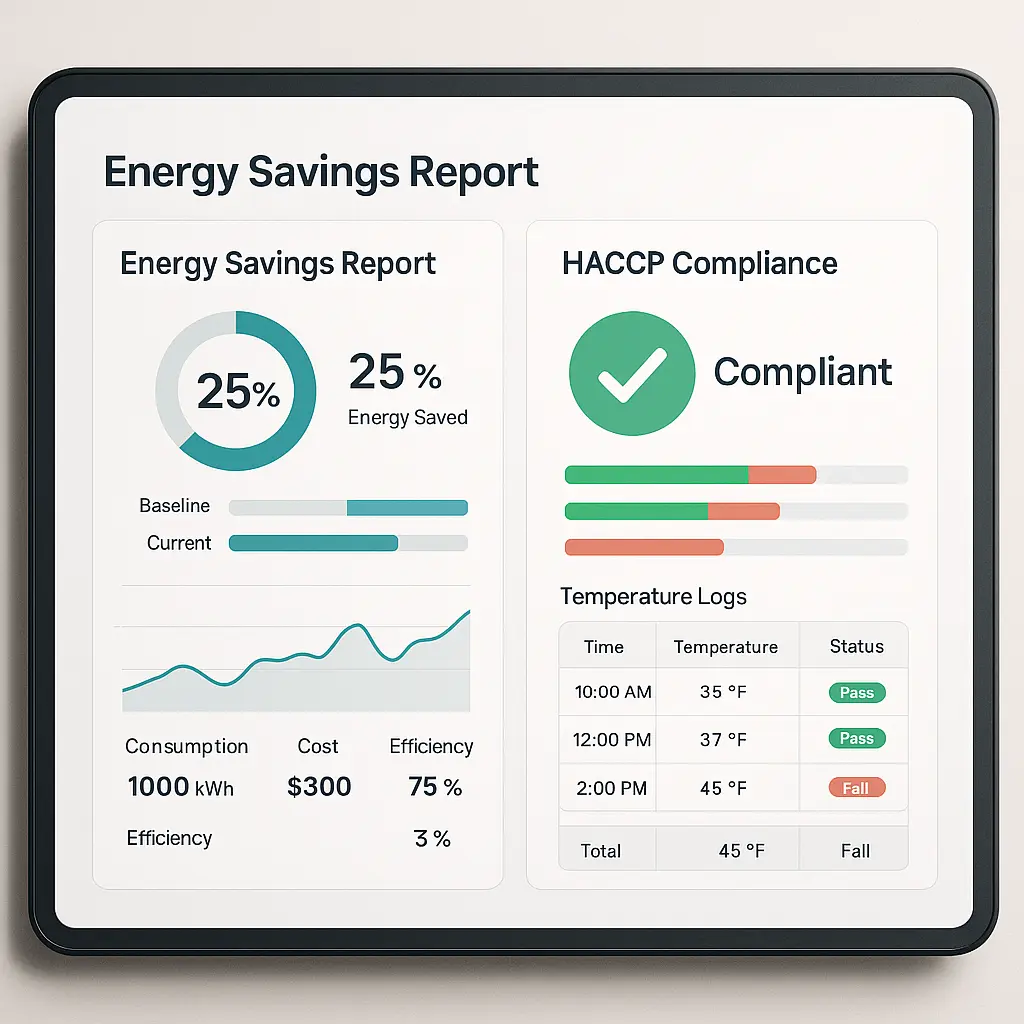

Case Study: Chain‑Wide Energy Savings

A national chain rolled out wireless sensors + smart thermostats across 300 stores:

- Control results: Temperature swing dropped from ±2°C to ±0.5°C; fresh quality improved.

- Energy savings: Average refrigeration electricity down 15% per store.

- Assuming $20k/year per store on refrigeration, that’s about $3k saved annually.

- Across 300 stores: $900k/year saved.

- Spoilage reduction: Temperature‑related product loss down 30%.

Traditional vs. Smart Thermostat

| Dimension | Traditional Thermostat | Smart Thermostat |

|---|---|---|

| Control accuracy | ±2°C | ±0.5°C |

| Energy performance | Fixed modes | AI + time‑of‑day, 10%–20% savings |

| Policy flexibility | Manual tweaks | HQ remote policies |

| Maintenance | Reactive | Predictive alerts |

| Data retention | None | Cloud‑based, audit‑ready |

Control Logic (Mermaid)

--- title: "Smart Thermostat Control Logic" --- flowchart TD A[Temperature Sensor Data] --> B[Smart Thermostat] B --> C{AI Decision} C -->|Too Warm| D[Increase Compressor Power] C -->|On Target| E[Hold] C -->|Too Cold| F[Reduce Power / Eco Mode] B --> G[Upload Runtime Data to IoT Platform] classDef sensor fill:#e3f2fd,stroke:#1e88e5,stroke-width:1px,color:#0d47a1; classDef controller fill:#ede7f6,stroke:#5e35b1,stroke-width:1px,color:#311b92; classDef decision fill:#fff3e0,stroke:#fb8c00,stroke-width:1px,color:#e65100; classDef action fill:#e8f5e9,stroke:#43a047,stroke-width:1px,color:#1b5e20; classDef cloud fill:#f1f8e9,stroke:#33691e,stroke-width:1px,color:#1b5e20; class A sensor; class B controller; class C decision; class D,E,F action; class G cloud;

Bottom line with sensors + smart thermostats

- Real‑time monitoring → auditable food safety

- Smart control → 10%–20% energy reduction

- Predictive maintenance → ~30% less spoilage

- Centralized ops → HQ control at national scale

Architecture & System Design

This isn’t a point solution; it’s edge‑to‑cloud architecture.

Layered Design

- Sensing Layer

- Wireless temp sensors, smart thermostats, humidity/door sensors.

- Capture telemetry and execute control.

- Edge Layer

- IoT gateway or edge compute.

- Local preprocessing and decisions to reduce cloud latency.

- Platform Layer

- Unified ingestion into the IoT platform.

- AI models for energy analysis and predictive maintenance.

- Integrations with WMS/ERP for replenishment triggers.

- Application Layer

- Refrigeration dashboards, compliance reports, energy optimization.

- HQ wallboard + store‑level real‑time alerts.

Architecture Diagram (Mermaid)

--- title: "Refrigeration IoT Architecture" --- flowchart TD subgraph S["Sensing Layer"] T1["Wireless Temp Sensors"] --> G T2["Smart Thermostats"] --> G T3["Humidity/Door Sensors"] --> G end subgraph ELayer["Edge Layer"] G["IoT Gateway"] --> E["Edge Compute Node"] end subgraph P["Platform Layer"] E --> P1["IoT Management Platform"] P1 --> P2["AI Energy Analysis"] P1 --> P3["Predictive Maintenance Engine"] P1 --> P4["Data Storage & Traceability"] end subgraph U["Application Layer"] HQ["HQ Ops Center"] P2 --> U1["Energy Optimization Reports"] P3 --> U2["Alerts & Work Orders"] P4 --> U3["Food/Pharma Compliance Reports"] end classDef sense fill:#e3f2fd,stroke:#1e88e5,stroke-width:1px,color:#0d47a1; classDef edge fill:#e8f5e9,stroke:#43a047,stroke-width:1px,color:#1b5e20; classDef platform fill:#fff8e1,stroke:#fbc02d,stroke-width:1px,color:#6d4c00; classDef app fill:#fff3e0,stroke:#fb8c00,stroke-width:1px,color:#e65100; classDef hq fill:#ede7f6,stroke:#5e35b1,stroke-width:1px,color:#311b92; class T1,T2,T3 sense class G,E edge class P1,P2,P3,P4 platform class U1,U2,U3 app class HQ hq

Use Cases Across Industries

- C‑Store Beverage Coolers

- Temp + door sensors track opening frequency.

- Auto eco mode at night saves ~15%.

- Supermarket Fresh Cases

- Multi‑point probes across shelves prevent local hot spots.

- Automated temperature curves simplify regulator engagement.

- Pharma Cold‑Chain Storage

- Tight tolerance ±0.5°C for sensitive products.

- GDP‑aligned traceability for audits.

- Restaurant Central Kitchens

- Smart control + humidity sensing optimize preservation.

- Longer freshness, less waste.

👉 Want to see how centralized refrigeration control fits into your digital retail operations? Explore our[ cloud-based retail software.]

Grocery Store Refrigeration System and More Retail Benefits from Smart Store Refrigeration Management

Smart refrigeration delivers measurable value across different store formats:

- Grocery stores: Multi-point sensors keep produce fresher while cutting energy costs.

- Restaurants and central kitchens: Precise temperature and humidity control reduce waste and ensure food consistency.

- Convenience stores: Eco modes on beverage coolers save up to 15% of refrigeration energy.

- Pharma retail outlets: ±0.5°C accuracy protects sensitive drugs with GDP-compliant traceability.

Across these scenarios, the benefits are consistent: safer products, lower operating costs, and smoother compliance audits.

What’s Next

- Edge AI

- More inference at the store for millisecond decisions.

- Sustainability & Carbon Tracking

- Refrigeration integrates with ESG reporting.

- Digital Twins

- Simulate cases to predict energy and maintenance windows.

- Cross‑System Orchestration

- Coordinate refrigeration with other store devices (e.g., boost cooling during traffic peaks).

Refrigeration has evolved from “cut the power bill” to guarantee safety, ensure compliance, enable smart ops, and support green goals.

By combining wireless sensors + smart thermostats + an AI platform, retailers can:

- Monitor temperatures in real time with confidence.

- Cut refrigeration energy by 10%–20%, saving hundreds of thousands at chain scale.

- Reduce spoilage with predictive maintenance and build a more resilient supply chain.

Ready to deploy a wireless refrigeration monitoring system for your stores? [Get a tailored demo]starting from $9.99/month.

cold chain compliance, energy management in retail, grocery store refrigeration system, multi store management system, refrigerator temperature monitoring, restaurant refrigeration monitoring, retail store management software, smart store refrigeration management, smart thermostat, wireless temperature monitoring system