Overview

ZedIoT delivered a high-accuracy resistive sensor array solution for an industrial client, enabling real-time data acquisition and automated calibration through custom PCB hardware and upper computer software. The solution replaced legacy systems and established a foundation for edge-to-cloud IoT deployment.

Client Background

The client operates in precision manufacturing and requires accurate voltage readings from resistive sensor arrays to calibrate equipment and log test data. Existing tools were unreliable, costly, and lacked integration capabilities.

Key Challenges

- Unable to capture stable readings from high-density sensor arrays

- Overreliance on third-party DAQ tools with poor customization

- No unified software interface to streamline testing or export data

ZedIoT Solution

ZedIoT delivered a full-stack solution combining custom hardware and tailored software to address the client's sensor accuracy challenges. We designed a multi-channel PCB for precise analog signal capture and developed an upper computer interface for real-time monitoring and streamlined calibration. The system supports edge-to-cloud integration, enabling both local deployment and future IoT expansion. This modular approach ensures scalability and adaptability across industrial use cases.

Custom PCB for Sensor Data Acquisition

ZedIoT designed a dedicated analog board featuring:

- 64 input channels with low-noise routing

- Buffering op-amps and anti-aliasing filters

- Modular connectors for sensor grids

- Integration with a 16-bit ADC module

This PCB ensured precision voltage capture across all resistive input nodes.

Precision Voltage Measurement Circuit

The analog front-end was engineered for high accuracy:

- Low-drift signal amplification

- Reference-stabilized voltage conditioning

- Noise isolation for industrial interference environments

Together, these components achieved sub-1mV resolution in typical factory noise conditions.

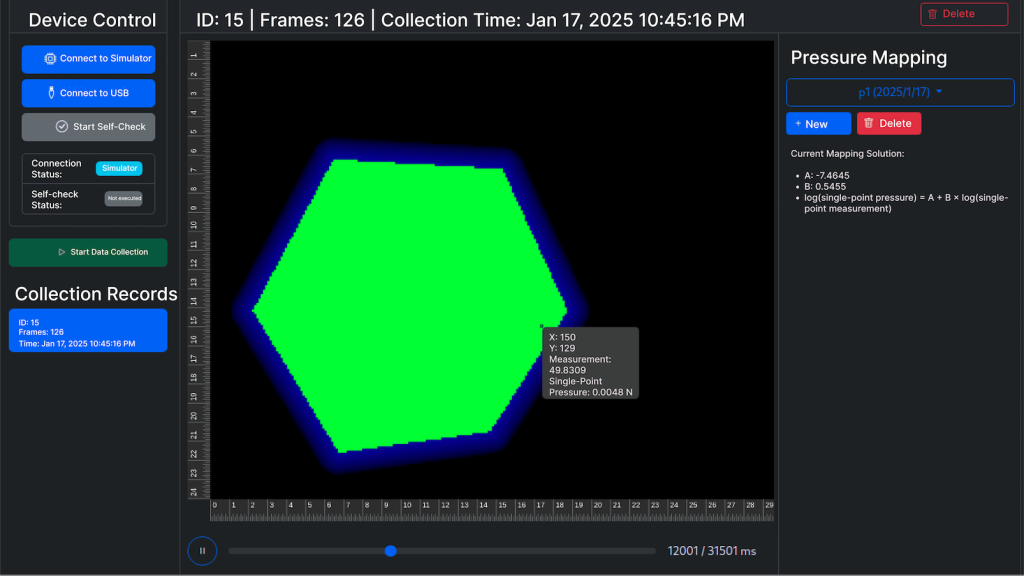

Upper Computer Software Customization

We developed a bespoke HMI tool for engineers and QA staff:

- Real-time matrix visualization of all sensor points

- Auto-calibration and sweep test functions

- CSV/JSON export with batch labeling

- MQTT/SCADA readiness for future integration

The interface was built around operator feedback, reducing the learning curve and workflow friction.

Industrial IoT Sensor Application (Future-ready)

While the deployment was local-first, the system supported:

- Edge gateway handoff (REST + MQTT)

- Device ID mapping + timestamp precision

- Future linkage to cloud dashboards or ERP systems

System Architecture

graph TD A["Resistive Sensor Grid"] --> B["Custom PCB Interface"] B --> C["Analog Signal Conditioning"] C --> D["High-Resolution ADC"] D --> E["Upper Computer HMI Software"] E --> F["CSV/JSON Export"] E --> G["Optional Cloud / SCADA Integration"]

System Dashboard

Results

- Achieved stable 0.8mV precision across all channels

- Cut per-device calibration time by 40%

- Replaced $3,000/year software tool with an in-house HMI

- Enabled downstream IoT roadmap with plug-in architecture

- Positive client feedback: “Reliable, simple, and finally unified”

Technical Comparison

| Component | Before | After (ZedIoT) |

|---|---|---|

| Signal Accuracy | ~5 mV fluctuation | ≤1 mV stable |

| Sensor Channels | 8 max | 64 scalable |

| Software Export | Manual only | Realtime CSV + API |

| UI Experience | Generic tool | Workflow-aligned UI |

| IoT Compatibility | None | Edge-ready MQTT/REST |

Replicable Value

This solution is adaptable to any scenario requiring real-time, high-accuracy analog sensing, such as:

- Tactile robotics

- Smart beds and diagnostic pads

- Environmental force mapping

- Lab-grade calibration instruments

ZedIoT’s modular design ensures quick customization across verticals.

FAQ – Common Industry Questions

Q1: What types of resistive sensors are supported?

A: Any analog resistive device, including FSRs, strain gauges, and pressure sensors.

Q2: Can I integrate this with our SCADA system?

A: Yes. We support MQTT and Modbus TCP for SCADA/PLC data flow.

Q3: Does it support dynamic sensor re-mapping?

A: Yes. You can reconfigure the matrix layout directly in the software UI.

Q4: How long does it take to deploy?

A: Most clients complete hardware/software deployment within 1–2 weeks.

Q5: What if I want cloud dashboards later?

A: The system is built API-first. You can integrate any backend you choose.

Tired of Unstable Readings? Let’s Fix That

ZedIoT’s resistive sensor array solution offers precise voltage capture, scalable hardware, and intuitive software—all built for industrial use. Whether you're calibrating equipment or preparing for IoT integration, this solution is cost-efficient, customizable, and proven in production.