Background

For modern data centers, consistent server performance is essential for business continuity. Traditional data center monitoring tools mainly track software-level metrics—CPU usage, temperature, disk health, power readings, and fan speed. These methods are effective, but they often fail to capture early-stage mechanical issues that occur before system indicators change.

Common pain points include:

- Mechanical noise appears before software metrics fail (e.g., fan friction, coil whine, relay chatter).

- Minor acoustic anomalies are easy to miss during manual inspections.

- High-density server rooms create noisy environments where operators struggle to pinpoint the exact source of abnormal sounds.

To bridge these gaps, the customer sought a data center monitoring solution capable of detecting physical and electrical issues earlier and more accurately.

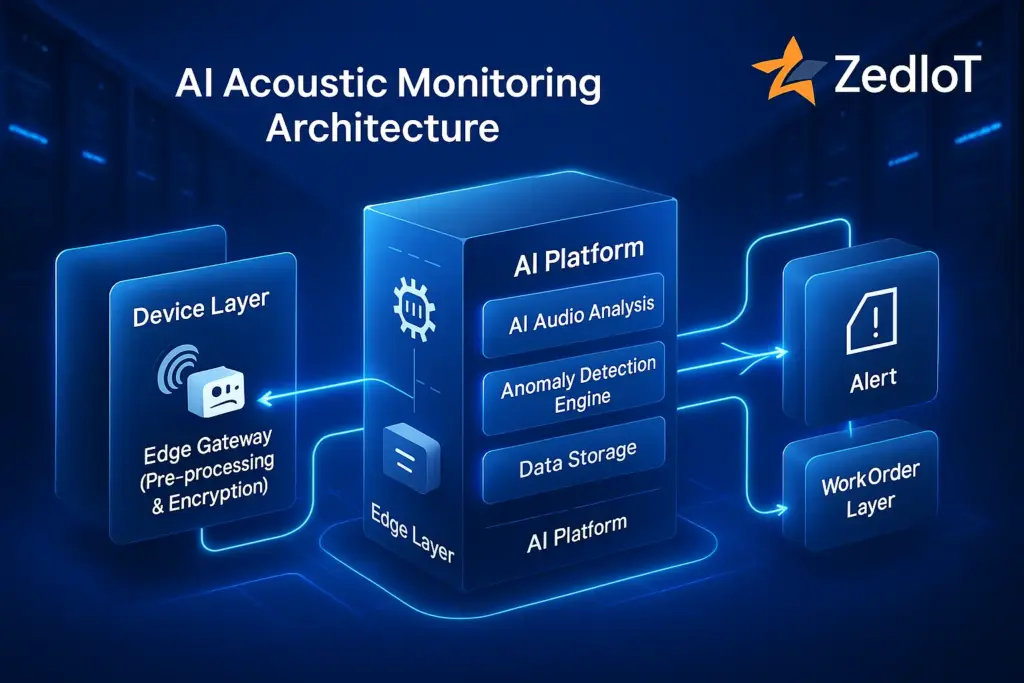

Our Solution: AI Acoustic Monitoring

We designed a full-stack solution that brings AI sound recognition into the data center environment. The system listens for micro-changes in server acoustics, identifies anomalies, and integrates them with existing monitoring platforms. This allows teams to detect issues earlier and automate responses with AI predictive maintenance capabilities.

1. Intelligent Acoustic Sensing Layer

- High-sensitivity sensors are installed near server racks, cooling modules, and power units.

- Sensors capture real-time acoustic signatures without requiring hardware modification.

- The deployment is brand-agnostic—compatible across different server vendors.

2. Edge Gateway (Pre-processing & Encryption)

- The edge node filters background noise, compresses audio, and encrypts data.

- This reduces bandwidth usage and preserves data privacy inside the data center network.

3. AI Acoustic Analysis Platform

- A deep-learning model analyzes sound patterns and builds a “normal” acoustic baseline.

- The system identifies anomalies using an ai sound identifier engine capable of detecting:

- Fan degradation

- Power supply oscillation

- Vibration irregularities

- Bearing wear and mechanical friction

- The platform supports real-time inference and continuous learning.

4. Multi-System Integration

- The system integrates seamlessly with Zabbix, Nagios, and Prometheus.

- When abnormal sound is detected, it correlates acoustic data with system metrics such as temperature, voltage, and RPM to reduce false alarms.

5. Automated Alerts & Workflows

- Alerts are categorized by severity and pushed via app, email, SMS, or WeChat.

- Automatic work orders are generated for maintenance teams.

- Each anomaly is traced back to the specific rack and device for rapid troubleshooting.

Technical Advantages & Business Value

| Advantage | Software Resource Monitoring | AI Acoustic Monitoring |

|---|---|---|

| Detection Scope | System indicators | Early mechanical and electrical issues |

| Response Speed | Alerts after metrics spike | Alerts as soon as abnormal sound appears |

| Deployment | May require vendor-specific adaptations | Plug-and-play sensors, vendor-agnostic |

| Fault Location | Often requires manual checks | AI identifies device and fault type |

| Operations Efficiency | Reliant on manpower | 24/7 unattended monitoring |

Results

1. Earlier Fault Detection

The customer identified hardware risks days or weeks before traditional monitoring tools would have flagged them. Common early-detected issues include:

- Fan wear and airflow inconsistency

- Power supply coil whine

- Hard-drive spindle vibration

- Intermittent relay chatter

These insights significantly reduce the chances of downtime.

2. Higher Accuracy With Multi-Signal Correlation

By combining acoustic patterns with temperature, power, and RPM data, the system achieved:

- Fewer false positives

- Fewer unnecessary site inspections

- More precise root-cause analysis

3. Reduced Operational Cost

The data center reduced manual night-time and weekend inspections, while maintenance efficiency improved 30%+.

4. Scalability and Compatibility

- Works with all major server brands

- Easy to expand during data center growth or relocation

- No vendor lock-in or hardware modifications required

Customer Feedback

Throughout the deployment, we worked closely with the customer’s operations team to validate acoustic patterns and tune alert thresholds. The system helped them discover several issues that had gone unnoticed, proving the value of AI-driven monitoring in a real production environment.

“Traditional monitoring tools often missed early mechanical issues. With AI acoustic monitoring, our team can catch anomalies before they escalate. It has significantly improved our operational stability and reduced workload.”

Conclusion

AI-driven acoustic monitoring adds a missing layer of intelligence to data center monitoring. By combining AI predictive maintenance, acoustic anomaly detection, and automated workflows, the solution strengthens data center reliability from both the software and physical layers.

As more enterprises seek to modernize data center monitoring solutions, AI acoustic systems will become a critical component—helping operators prevent failures, extend hardware lifespan, and protect business continuity.

Looking to enhance your data center monitoring with AI?

Contact ZedIoT for a free technical consultation and discover how AI acoustic monitoring can help you detect early hardware faults, reduce downtime risk, and improve predictive maintenance performance.