Industry & Background

Industry: Industrial IoT / Environmental Monitoring

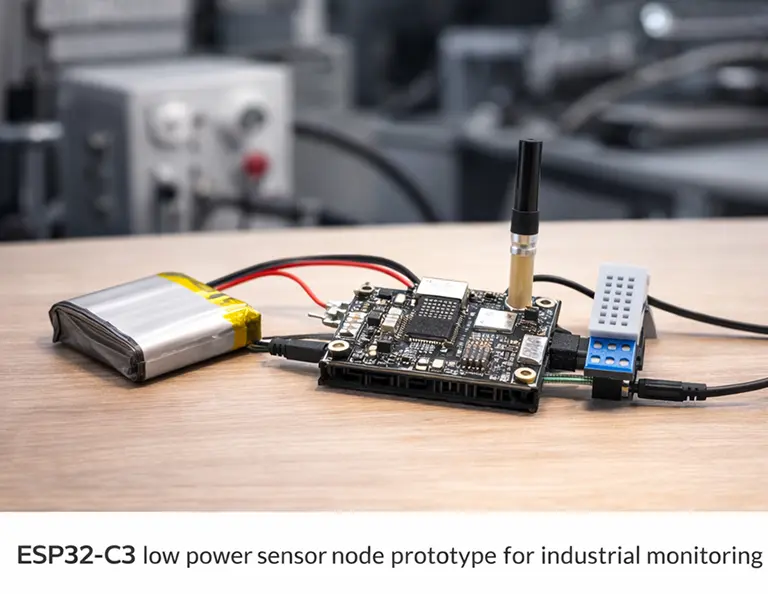

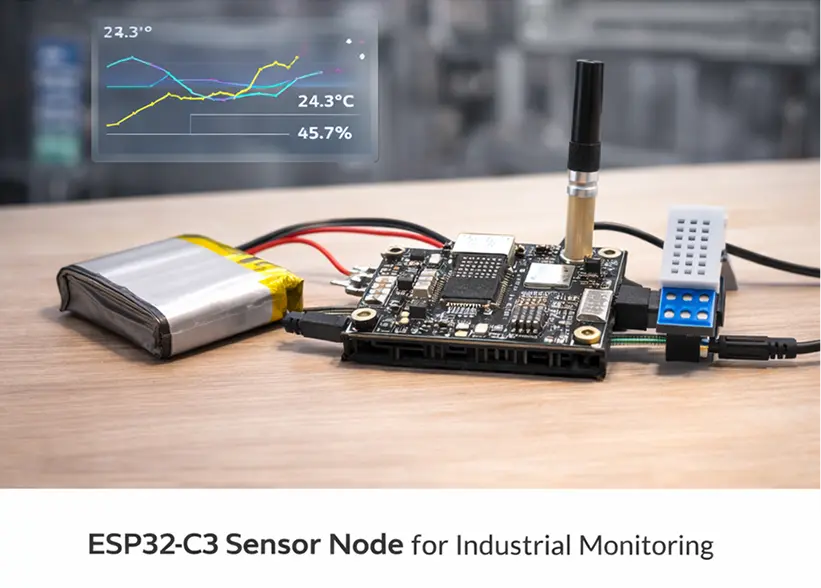

This case documents our work in ESP32 low power sensor node development for industrial monitoring scenarios where devices must operate reliably over long periods with strict power constraints.

The client operates in the industrial monitoring space, focusing on environmental data collection across distributed locations such as factories, storage facilities, and infrastructure sites. These environments typically require sensor nodes to function unattended for months or even years, often powered by batteries or limited energy sources.

The client was exploring ESP32-based solutions but needed guidance on how to design a low-power ESP32 sensor node that could balance energy efficiency, data reliability, and long-term maintainability.

Why the Client Contacted Us

The client approached us during the early planning phase of their industrial IoT deployment. While they had clear functional requirements, they faced uncertainty around power optimization and firmware architecture.

Specifically, they were looking to build a sensor node capable of:

- Long-term operation under strict power budgets

- Periodic and reliable data transmission

- Stable behavior in electrically noisy industrial environments

They were aware that ESP32 offered strong connectivity features, but wanted to ensure that ESP32 low power sensor node development was feasible for their use case—particularly when targeting multi-year battery life.

ESP32-C3 IoT Sensor Architecture

After reviewing the project requirements, we recommended ESP32-C3 as the core platform. Compared to other ESP32 variants, ESP32-C3 provides an effective balance of power efficiency, connectivity, and cost, making it suitable for industrial sensor nodes.

Our work focused on defining a practical ESP32-C3 IoT sensor architecture, including:

- Chipset selection aligned with low-power operation goals

- Sensor interface planning based on sampling frequency and accuracy needs

- Firmware architecture designed around periodic wake-up cycles

Rather than treating ESP32 as an always-on device, the architecture was designed to keep the system in deep sleep for most of its lifecycle, waking only when data acquisition or transmission was required.

Low Power ESP32 Firmware Optimization Strategy

A major part of this project involved defining a firmware strategy specifically tailored to low power ESP32 firmware optimization.

Key considerations included how often the device should wake up, how long it should remain active, and how to ensure data integrity without unnecessary energy consumption.

We worked with the client to outline a firmware approach that emphasized:

- Controlled deep sleep and wake scheduling

- Power-aware sensor polling strategies

- Reliable data transmission intervals optimized for energy usage

By carefully coordinating sensor sampling, processing, and communication tasks, the firmware minimized active time while still meeting monitoring requirements.

Project Status & Outcome

The outcome of this engagement was not a mass-produced device, but a clear and validated development strategy for ESP32 low power sensor node deployment.

The client gained:

- A structured ESP32-C3 firmware architecture for low-power operation

- Clear guidelines for sensor integration and wake-cycle management

- Confidence that ESP32 low power sensor node development could meet industrial monitoring constraints

This foundation allowed the client to proceed with implementation and internal testing, with a clear roadmap for future iterations.

Related ESP32 Sensor Development Experience

This case reflects our broader experience in ESP32 low power sensor node development for industrial IoT systems. It highlights the importance of treating power optimization as a system-level design challenge rather than a single firmware setting.

For teams evaluating ESP32-based sensor nodes for industrial monitoring, this project demonstrates how careful architecture planning and firmware strategy can significantly extend device lifespan without sacrificing reliability.

If you are planning a similar industrial deployment, our ESP32 hardware and firmware development services cover low-power sensor design, ESP32-C3 firmware optimization, and production-ready architecture.